Going through a major equipment replacement can be a stressful experience for ship managers and crew, especially when it comes to an essential piece of machinery like Air Conditioning Chillers. These units may last several years, are reliable and usually don’t require any major maintenance apart from periodic cleanings.

So why do Shipowners decide to replace them? The key word is efficiency. Chillers, especially on passenger ships, are among the largest consumers of energy besides propulsion. Thus, newer and more efficient models can immediately help to reduce fuel consumption, operating costs and emissions, all while delivering higher performance and improving comfort on board.

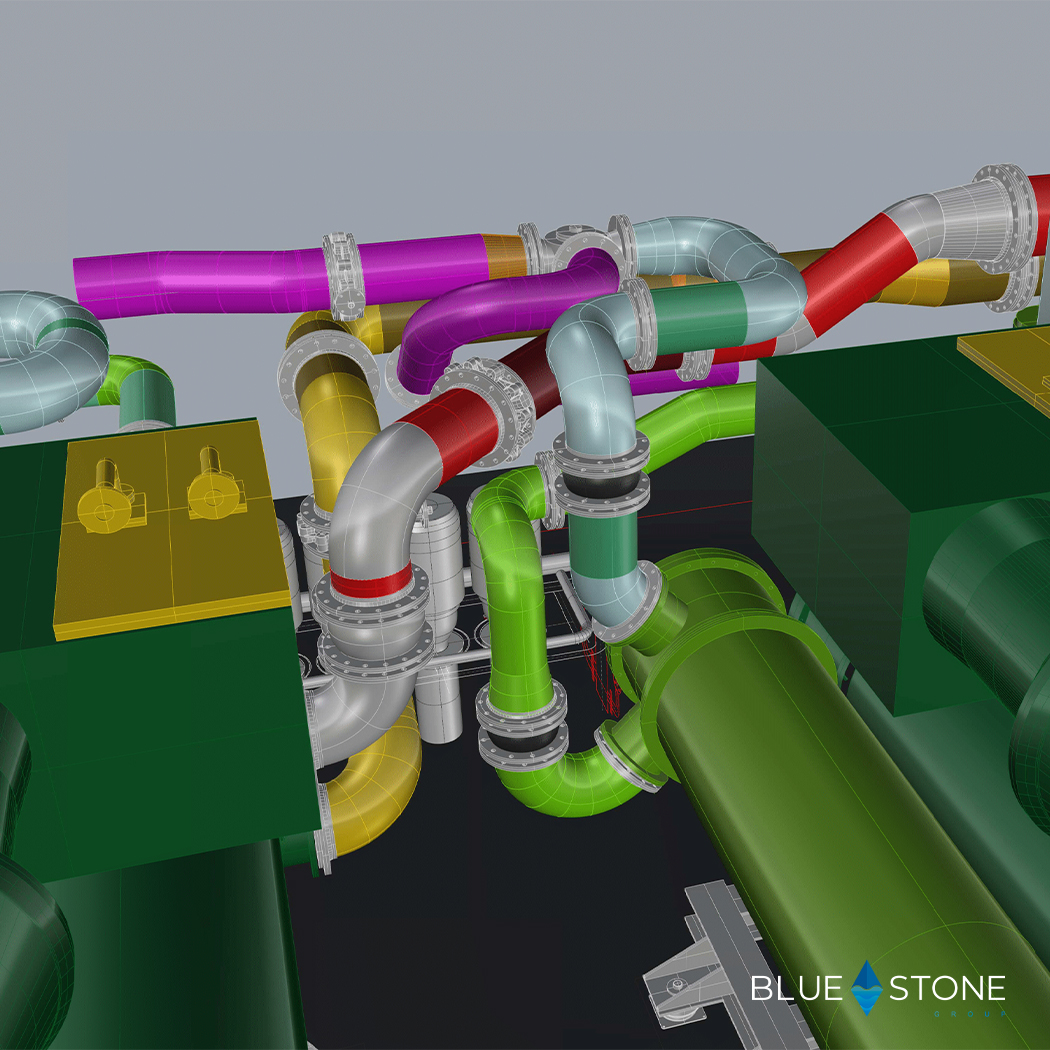

Bluestone has executed several chiller replacement projects on board different cruise vessels. The job starts with a technical documentation review of existing systems, complemented by an on-board inspection and laser scan to determine the true condition of all related components, pipes, electrical equipment and, last but not least, to assess available space.

Required cooling power usually changes when replacing the chiller, and an evaluation of the current performance and future use of the HVAC system helps to ensure that the new unit is sized properly. If the chiller capacity has indeed increased, an upgrade of the ancillary systems and equipment is most likely required and should be carefully assessed.

Once the new system design has been accepted by the owner, it’s time to plan the replacement activities. Due to their considerable size, weight and low installation position in the ship hull, one of the biggest challenges is accessing the work areas. The most common solution Bluestone adopts entails cutting a side opening on the hull under the waterline, installing a steel platform on the dock bottom, removing the existing chillers and installing a new one in its place by means of air hoists and a system of tow lines and sliding blocks.

Once the new equipment is installed in its final position, all pipes are restored together with their relative insulation. The existing medium voltage cables are reconnected and dedicated new cable trays are installed. New LUG terminals are installed and dielectric tests are carried out on the cables prior to putting the new units in service.

The operation was of course carried out during a pre-planned dry dock when the ship wasn’t floating, so as to cut the hull below the waterline and avoid any downtime, costs and inconveniences.

Key figures:

- 30 day full installation

- 30 tons: weight of each chiller unit